The increasing demand for new and renovation hospitality construction in the U.S. offers builders a significant opportunity. In a recent U.S. Construction Pipeline Trend Report from Lodging Econometrics, analysts report that hotel construction pipeline projects in the U.S. rose nine percent at the close of Q1 2023, and is attributed much to the robust travel demand recovery. Hotel renovation and brand conversion in the U.S. continues to boom, and has increased by 38 percent between 2022 and 2023.

Unfortunately, the building industry struggles to take advantage of these construction opportunities due to labor shortages and supply chain problems, which can slow, if not stop, construction schedules.

For building companies to benefit from the current hospitality construction market, they must redirect their building practices towards cost-effective building materials and less labor-intensive construction methods, like prefabricated construction.

What is Prefab Construction?

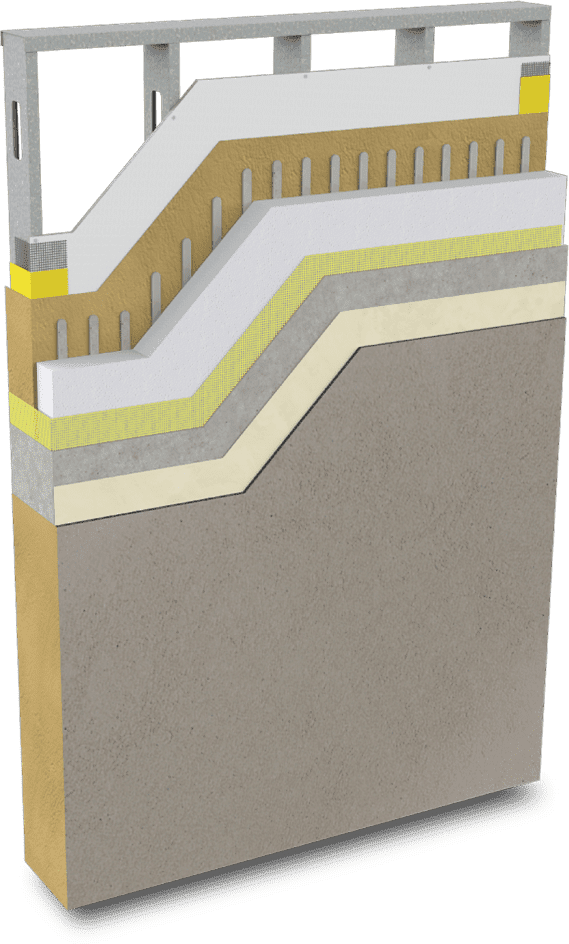

Experienced fabricators manufacture customized, project-specific finished exterior wall panels to specifications that meet requirements for fully-engineered, tested and code compliant systems. The prefab walls include exterior cladding (like stone, wood, stucco, or other material), fenestration, air/water/vapor barrier control systems, insulation, flashing, and structural framing. After transporting the prefabricated wall systems to the job site, a relatively small number of workers can lift and install the prefabricated panels following the architect’s plans.

Sto Panel Technology® Prefabricated Wall Panels

Sto Panel Technology® prefabricated wall panels provide architects and contractors with a superior sustainable solution to many of the challenges of hospitality construction, including labor shortages and supply chain problems, to help ensure that the projects stay within budget and on time, and meet code and safety requirements. Prefabricated construction offers building owners long-lasting and energy-efficient complete building envelope systems with a wide variety of aesthetic facade choices

Why Use Prefab Construction in Hospitality?

Prefab construction for new and renovation projects adds many short and long-term benefits to the hospitality industry to help ensure the financial success of their businesses.

Hastens the Construction Timeline

Prefabrication quickens the completion of the hotel’s exterior, to save money and allow for quicker access to the hotel’s interior. Prefab hospitality construction will enable owners to begin collecting revenues sooner.

Prefabrication quickens construction timelines because:

- Installation takes days or weeks, not months, like conventional construction

- Manufacturing in a controlled manufacturing environment eliminates weather or other field conditions that can delay construction schedules

- Allows workers to complete a vertical expansion of a hotel quickly

- Manufacturing panels in quality-controlled factories allows for building envelope inspection, testing, and checking before installing at the project site

Helps Hospitality Projects Stay on Budget

Choosing prefab construction will help hotel owners save money, which allows them to redirect those savings elsewhere on the project:

- Lightweight panels reduce job site labor, require less specialized trades, limit the use of scaffolding, and lessen structural needs

- Minimizes debris and construction waste and debris, which saves money

- A single-source warranty to give owners added protection

Improves Quality Control

Manufacturing of prefabricated wall panels occurs in a climate-controlled indoor environment by an experienced crew and precise machine equipment. The process ensures uniform quality between the sub-assemblies of the structure and conformity to the building code.

Sustainable, Prefabricated Wall Panels

A sustainable hotel aims to minimize water and energy use, limit carbon emissions, and create long-lasting hospitality buildings – all features that save time and money on repairing or rebuilding. Builders can also quickly retrofit an existing hotel with prefabricated wall panels, an aesthetic, energy-saving, economical, and sustainable alternative to new construction. Sustainable benefits of prefab construction include:

- Manufacturing prefab walls inside a facility can cut job site waste compared to traditional construction. It also allows for the in-house recycling of materials.

- The controlled environment of a prefabricated factory ensures more precise construction, tighter joints, and adequate storage of materials, to enhance the final product’s overall quality and energy efficiency.

- Factory-built construction significantly reduces truck traffic, material suppliers, and equipment around the job site, which minimizes soil disturbance and erosion of the area.

Aesthetic Flexibility of Prefabricated Wall Panels

A well-designed, aesthetically pleasing hotel helps attract visitors and enhance their experience so they will return and recommend your hotel to other travelers.

Prefabrication offers architects several significant aesthetic benefits:

- Design flexibility allows architects to match or complement the aesthetics of the original building.

- Provides a way to quickly rebrand a hotel without completely rebuilding.

- Aesthetic flexibility, from a modern, sleek design to classic metal, brick, and stone.

Hilton Home 2 Suites

Hilton Home 2 Suites

Location: Philadelphia, PA

Building Type: Hospitality

System Type: Prefabricated Wall PanelsPanel Type: StoPanel® Classic ci

Construction Type: New

Construction Method: Prefabrication

Hyatt House

Hyatt House

Location: Nashville, TN

Owner: Songy Highroads

General Contractor: Reeves & Young

Architect: Wakefeld Beasley & Assoc.

Building Type: Hotel

Onsite Assembly Date: 2018

Panel Type: StoPanel® Classic NExT ci

Utilizing prefabricated, quick and easy-to-install StoPanel® Classic NExT ci panels with an acrylic textured finish provided the building team with a means to accelerate the time schedule and achieve a stunning hotel with a durable, self-cleaning Lotusan finish.

Hilton Canopy Hotel

Hilton Canopy Hotel

Location: Tempe, AZ

Owner: Driftwood Hospitality Management

General Contractor: Sundt Construction

Architect: Allen + Philp Partners

Engineer: Engineer of Record – PK

Engineer for panel system via MKB: Lochsa Engineering

Building Type: Hotel

Onsite Assembly Date: 2nd Quarter 2019

Panel Type: StoPanel® Classic NExT ci and StoPanel® Dri-Design®

Kapture Prefab used StoPanel® Classic NExT ci with StoPanel® Dri-Design® panels to meet the challenges of a unique design, quick timeline, and tight job site:

The Arizona State University hotel required installing StoPanel® Dri-Design® metal panels on the building’s exterior so that the colors and panels represent the notes of the school’s fight song. StoPanel® prefabrication lessened the time schedule by three months compared to traditional construction methods.

Closely surrounded by buildings, one of them just 3 feet away, workers could safely position the prefab panels using controlled taglines and a tower crane.

Great Wolf Lodge

Great Wolf Lodge

Location: Scottsdale, AZ

Owner: Great Wolf Lodge

General Contractor: Mortenson

Architect: Gensler Engineer ASE

Building Type: Hospitality

Onsite Assembly Date: August 2019

Panel Type: StoPanel® Classic NExT ci

Kapture Prefab chose StoPanel® Classic NExT ci panels to overcome installation access issues. In addition, the project needed to limit disruptions to a neighboring big-league spring training center. The prefabricated panels cut the timeline by 6 to 8 weeks. They also mitigated job site debris and construction noise, which benefited the nearby big-league facility.

Aloft & Element Hotel

Aloft & Element Hotel

Location: Austin, TX

Owner: White Lodging

General Contractor: DPR Construction

Architect: HKS Dallas

Engineer: Matsen Ford Design

Building Type: Hospitality

Onsite Assembly Date: Summer 2017

Panel Type: StoPanel® Classic ci and StoPanel® Dri-Design®

Utilizing StoPanel® Classic ci and StoPanel® Dri-Design® on the facade of the White Lodging hotel required only six onsite workers. Furthermore, prefab construction accelerated the dry-in schedule and enhanced the aesthetic appeal in downtown Austin.

Choose Sto Panel® Prefab Technology for Your Next Hospitality Project

Sto Panel Technology® offers builders and architects of new and renovation hospitality projects extensive design flexibility while meeting their performance, scheduling, and budget demands. Our prefabricated wall panels contribute to durable, energy-efficiency, and low-maintenance hotels, all features that will save time and money!

Contact one of our experts today at 800-545-6087 or download Industry Shift: The Acceleration of Panelization to learn more about prefab construction in hospitality.