Sto Panel® Technology’s fully engineered, tested, and warranted prefabricated finished exterior wall panels provide commercial architects, contractors, design consultants, and owners with a less labor-intensive solution that reduces building envelope installation time without sacrificing quality and allowing building professionals to take advantage of the increasing construction market.

Utilizing StoPanel® Classic NExT ci panels for this mixed-use building in Ontario, Canada, allowed builders to cost-effectively hastened the installation of its energy-efficient building envelope.

Rising Construction Market

The Global Buildings Construction Market size in 2022 was $5,412.80 billion. Building experts predict this figure to grow to $11,121.90 billion by 2030 at a compound annual growth rate (CAGR) of 7.4 percent for new construction, additions, alterations, maintenance, and repairs.

Many builders may find it difficult to benefit from these unprecedented opportunities due to supply chain problems and labor shortages (both challenge builders to stay on schedule), costing money and frustrating clients. Furthermore, many builders report postponing or canceling projects due to rising labor and material costs.

Labor Shortages Continue in 2023

The continuing lack of unskilled and skilled construction workers makes it challenging for building professionals to stay on schedule and within budget. According to Associated General Contractors of America’s 2023 Construction Outlook National Survey, 80 percent of building professionals report difficulty filling salaried and hourly craft positions, with 58 percent predicting this will continue or worsen over the next 12 months. To attract workers, 72 percent of building professionals reported increasing base pay rates between 2021 and 2022.

Supply Chain Woes in 2023

Volatile prices and availability of construction materials due to supply chain issues create long lead times, which makes it challenging to estimate project costs accurately.

Notably, building professionals’ most significant concerns for 2023 include the following:

- Project delays due to supply chain issues (63 percent)

- Material costs (73 percent)

As a result, many builders are turning to alternative suppliers, materials, products, and solutions, like Sto Panel® Technology.

Hasten Building Envelope Installation Time with Sto Panel® Technology

Easy and efficient to install, fully-engineered, tested, and code-compliant Sto Panel® Technology prefabricated finished exterior wall panels offer the building industry benefits that can reduce high-performing building envelope installation time without sacrificing quality.

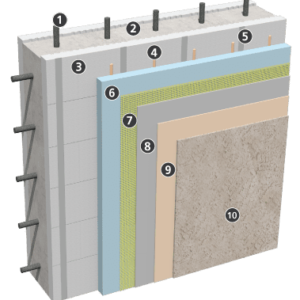

The StoPanel® system contains cold-formed metal framing and other valuable features, including continuous insulation, air and water-resistive barrier, glass mat sheathing, sub-framing, and various aesthetic surface options, including precast resin shapes, metal, brick, natural stone, and the modern, energy-efficient lightweight textured finishes and coating systems.

Panel Wall Construction Improves Quality Control of Building Envelopes

Prefabricated construction boards are manufactured in a climate-controlled, indoor environment with precise machine equipment and an experienced crew to ensure uniform quality between the structure’s sub-assemblies and building code compliance. Traditional site-built structures require coordination of independent contractors’ skill levels and schedules, which can affect the overall quality of the finished product.

Furthermore, fabricators can work out any problems in the factory setting before the product reaches the job site.

How StoPanel® Systems Accelerate Building Envelope Installation

Sto Panel® Technology can accelerate building enclosure schedules by up to 80 percent, by lessening overall building costs and allowing builders to realize profits sooner. However, the success of a project depends significantly on early planning and good communication between the general contractor, architect, and panel manufacturer.

Prefab construction reduces building envelope installation time over traditional methods by providing several significant benefits:

- Efficient upfront planning

- Limiting delays due to on-site weather factors

- Reducing subcontractor scheduling

- Allowing for the manufacturing of panels while builders complete the initial site work and structural framing of the building

- Improves workers’ safety and reduces the risk of worker injury that can lead to construction delays.

- Prefabricated wall panels come to the job site pre-assembled to drop into place with a crane, which eliminates scaffolding hazards and other on-site building methods for a multi-floor wall.

- Building off-site walls will lessen workers’ exposure to dangerous rain, wind, lightning, and changing ground conditions.

- Factory-controlled environments utilize dry materials, which reduces the risk of problems associated with moisture, dirt, and environmental hazards in order to help protect workers on the building site.

Prefab construction offers several other cost-saving advantages:

- Significantly lessens the number of skilled labor installers needed on the job site, which benefits contractors as they struggle with ongoing skilled labor shortages.

- Lowers security costs by lessening the risk of vandalism and theft on the project site.

- Reduces raw material waste at the job site by nearly 50 percent compared to conventional construction, saving money.

Kapture Prefab combined StoPanel® Classic NExT ci with StoPanel® Dri-Design® panels for the Hilton Canopy Hotel in Tempe, Arizona, to cut the building schedule by three months compared to conventional construction methods.

For this college dormitory, Jersey Panel replaced the metal panels with StoPanel® Classic ci panels. Prefabricating the panels off-site allowed for the building enclosure to be completed sooner, cutting months off the on-site construction time and guaranteeing a completion date ahead of the arriving students.

Reducing Building Envelope Installation Time Without Sacrificing Quality with Sto Panel® Technology

To benefit from the current-rising construction market, building companies must reduce building envelope installation time by rethinking their construction practices towards cost-effective building products and less labor-intensive building envelope solutions, without sacrificing quality, like that provided by Sto Panel® Technology.

Sto Panel® Technology is a superior option for efficient, sustainable, and safe commercial construction of a building envelope. Precisely manufactured in-house and delivered directly to the job site hastens the construction schedule with less labor and waste, to save both money and time. Prefab also enhances quality control and improves job site safety.

Get in touch with StoPanel® professionals today for more tips on reducing building envelope installation time without sacrificing quality or learn more about panelization by downloading The Acceleration of Panelization.